Whats new in Process Mineralogy Technology: The QEMSCAN EXpress

July 5, 2013

Value losses due to poor liberation and classification

July 16, 2013The importance of the liberation of target minerals in the feed to a flotation circuit is well recognised and understood by process metallurgists. This blog seeks to introduce some of the concepts around:

– how liberation is defined

-

– what the important parameters to understand are

– how liberation is defined by process mineralogists

Liberation measurements estimate the volumetric grade distribution of a mineral as a measure of the quality in a processing stream (Spencer and Sutherland, 2000). Put simply, it is based on the area % of the mineral grain in the particle: which brings us to the first key question – what is the difference between a “grain” and a “particle”?

The second critical question is to ask whether area % alone is enough to help predict how a particle will behave in a flotation cell – what about free surface area? A grain may be defined as 90% liberated, but have no free surface area… so will this recover more quickly or more slowly to the flotation concentrate than say a grain that is 60% liberated but has a high free surface area?

What is the difference between a “Grain” and a “Particle”?

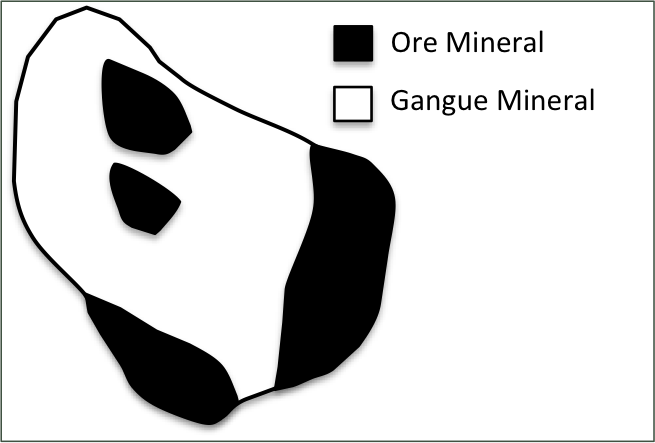

Typically, a “grain” is classed as a single mineral, whilst a “particle” is made up of one or more mineral grains. The figure below provides an example of a single “particle” that contains four mineral “grains”.

Example of a “particle” containing five mineral “grains” (4 black and 1 white)

Example of a “particle” containing five mineral “grains” (4 black and 1 white)

Liberation

In process mineralogy, the degree of liberation of a mineral is generally calculated from examining 2D sections of a statistically representative set of particles containing the mineral of interest. The degree of liberation is typically based on the area% of the mineral grain(s) of interest in a particle (figure below). Particles are usually classed in to particle grades of various incremental steps: these steps might be 10% increments (100% liberated, 90-100% liberated, 80-90% liberated etc), or as broader 30% steps such as <30% (locked), 30-60% (middlings) and >60% (liberated).

Free Surface Area

This calculation of ‘liberation’ is distinctly different to an estimate of the free surface area (or PSSA – phase specific surface area) of a mineral in a particle. The free surface area is again typically based calculations from examining 2D sections of a statistically representative set of particles, however as the name suggests it is an estimate of the % of the grain(s) of interest that has a free surface, and therefore have a surface accessible by bubbles in a flotation cell, or acid on a heap leach pad for example (figure below).

Understand how the data is derived in order to understand how to interpret it

The figure below combines these concepts, showing example particles containing ore mineral grains classified by both liberation % and free surface area %. These examples serve to highlight the influence of particle and mineral texture for grade and recovery calculations, and how critical it is to understand both degree of liberation and the free surface area. Both these textural classifications are critical for mineral processing, with the ideal particle of course having 100% liberation (and therefore by inference, 100% free surface area).

The essential point is that both liberation and free surface area should be considered when examining a feed ore and aiming to predict grade and recovery potential to a flotation concentrate.

The influence of liberation and free surface area is profound in flotation, leaching and even gravity circuits, where poorly liberated grains dilute the final concentrate. Understanding the degree of liberation using optical microscopy, automated mineralogy or more recently, micro-tomography to provide 3D liberation information, should be a primary concern for any process including a flotation circuit. MinAssist can assist you with developing cost effective and efficient programs to measure liberation and free surface area. We find this is an area that can generated significant value for an operation and if you are interested in a complimentary mineralogy assessment feel free to contact us for more information.

References:

Spencer, S and Sutherland, D 2000. Stereological correction of mineral liberation grade distributions estimated by single sectioning of particles. Image Anal Stereol 2000;19:175-182